Transparent and sustainable value chain

Our ‘Transparent and sustainable value chain’ key issue means we also want to have a positive impact on our upstream and downstream value chain and promote protection of the climate and environment there. To do this, we establish fair, trust-based, and constructive business relations with our suppliers and customers.

Supplier management

To ensure a comprehensive evaluation of our business relationships with the top 50 suppliers, we carry out a detailed annual assessment. We award points for criteria such as delivery and quantity reliability, product quality, pricing and reliability. These scores are weighted and combined to produce an overall result. If we fall short of the minimum number of points set, we work with the suppliers concerned to develop strategies to achieve the targets. This approach enables us to continuously maintain the quality of our supplier relationships at a high level and monitor costs at the same time. In recent years we have also integrated ecological and social aspects into our evaluation criteria. A particular focus here is on the innovative strength of suppliers in terms of green technologies and reducing the carbon footprint, which enables us to promote sustainable values in our supply chains.

Resource-efficient packaging

To increase resource efficiency and protect the climate, we use alternative packaging and packaging materials to reduce packaging waste both at our plant and on construction sites.

Since 2014 we have been offering "Cube-It-Simple" packaging in our range of liquid products. This environmentally friendly solution consists of a recycled outer carton and a plastic bag inside. The bag-in-box packaging saves up to 85 % plastic compared to conventional canisters and can be disposed of separately. As this type of packaging is not suitable for all applications on construction sites, we are constantly working on new solutions to replace conventional plastic canisters with more environmentally friendly materials.

Two years ago we successfully changed the material of our shrink film, which is used to secure our products on pallets. The new film contains 30 % recycled material. We are also using a 50 % reduction in film thickness as an inner lining in paper bags for some of our powder products, which enables us to halve our plastic consumption without compromising the storage stability of the products. The switch to a thinner film thickness for other product bags is still under review.

Canister and lid made from recycled plastic

After successfully completing the conversion of our canister packaging from new plastic to post-consumer recyclate (PCR) in 2021, we had to switch back to new material in some cases from mid-2022 due to isolated leaks in some plastic canisters. To ensure the quality and safety of our products, we carry out strict quality controls, whereby only fault-free canisters are used for filling. Before switching back to recycled plastic, all canisters are subjected to intensive testing. Our long-term goal is to convert all canister packaging back to PCR. The lids made from PCR material, which we have been using for two years, are still in use.

Bucket made from used plastic

We have already replaced the virgin material granulate in most of our buckets with recycled material in various proportions. Since 2016 we have been using sustainable containers made from post-consumer recyclates (PCR) and post-industrial recyclates (PIR). Since 2021 we have been offering variants for selected products that consist of almost 100 % PCR. However due to technical requirements, the lids of these buckets are still made of new plastic material.

The codex FG 370 and codex X-Fusion buckets have been converted to in-mold labeling (IML). With this technology the labels are shrink-wrapped directly into the buckets during production, which means that the bucket can be fully recycled together with the label. The IML container also enables an excellent print image and the full-surface display of the codex brand color.

In order to make packaging more sustainable, Uzin Utz Nederland bv has switched all adhesive buckets, canisters and B-component bottles to material made from post-consumer recycled material (PCR). The material has the same properties as virgin granulate and is used to produce recycled packaging for the Haaksbergen plant for the UZIN, PALLMANN and Arturo brands. This means that fewer fossil raw materials are required for production, which contributes to a reduction in CO₂ emissions.

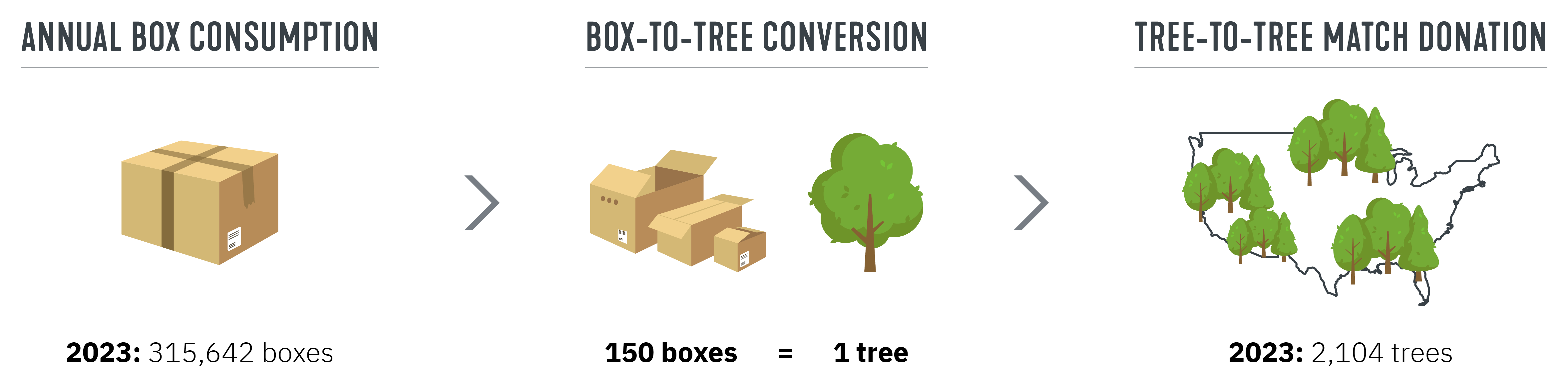

Planting trees to offset packaging waste

Since 2021 Uzin Utz North America Inc. has partnered with the National Forest Foundation (NFF) to help preserve national forests. As part of this cooperation we plant as many trees as are needed for the production of our corrugated packaging. Since the beginning of the partnership almost 10,000 new trees have been planted to date, which represents a significant contribution to the reforestation of national forests and at the same time counteracts the environmental impact of our cardboard packaging. Additionally we partner with Green Bay Packaging Inc. to ensure that our packaging fiber materials come from responsible sources. Our packaging resulting from this collaboration is labeled with the Sustainable Forestry Initiative® label, which is the leading seal for responsible fiber sourcing in the United States.